UV curing CIPP hose is a kind of glass fiber material pre-impregnated in the factory. In the use stage, the installation of the CIPP hose on site must be successful at one time, there is no possibility of repeated operation, so how to standardize the operation, adjust the appropriate pressure inflation, control the curing speed, control the resin heat release, and judge the curing degree is a cross-industry professional work.

This construction requires the technicians with a variety experiences in composite materials, water supply and drainage, trenchless repair construction to be present for guidance. However, the case to be told today, the original pipeline not only reached the third level of damage, but also faces extremely challenging working conditions such as three changes in diameter change, subsidence, and turning. The success of this emergency repair case also proves that UV-curable CIPP repair technology is a reliable method for drainage pipe repair.

Case sharing

01 Project Overview

This project is located on the main road of Central Zirui Avenue, Chengdu City, with a large traffic flow. The disease pipe network is located under the main road Shenshu Viaduct, and the road surface has been submerged in a large area, covering an area of about 160 square meters and a depth of about 20 cm. The pipe diameter of the pipe network is DN800-1200 (3 types DN800,DN1200, DN1000), and the pipe is concrete pipe. The length is 48 meters, the depth is 9 meters, and the construction period is about 20 years.

02 Construction Environment

1 Located on the green belt under the elevated main road, the traffic flow is large and the construction time is tight

2. The available space of the construction position is narrow, and the opening of the construction well is about 2.5 meters from the lowest point of the bridge, and the highest point is only 4 meters.

03 Construction technical difficulties

1. Due to soil erosion, the unstable foundation of the pipeline causes the pipeline to sink slightly.

2. The transverse displacement of the sinking pipe is S-shaped about 50cm, and the sinking depth is about 80cm.

3. In the case of poor linearity of the pipeline, it is necessary to ensure that the lining material is cured to ensure that the inner membrane is not broken and flooded.

4. Pipeline models are diverse, the materials need to have sufficient flexibility to respond to the requirements of different types of pipelines, at the same time, the requirements for construction are very high.

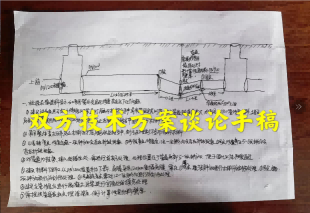

The after-sales department of Youwei New Materials has discussed reliable construction plans with customers for many times, and finally determined the technical plan of UV curing repair + grouting reinforcement with equal pipe diameter with the consent of the owner, the designer and the customer.

Construction environment drawing

(Authorized by Youwei New material customers only to use in this public number, readers please do not reprint)

04 Solution

Step1

This project is located on the main road of Central Zirui Avenue, Chengdu City, with a large traffic flow. The disease pipe network is located under the main road Shenshu Viaduct, and the road surface has been submerged in a large area, covering an area of about 160 square meters and a depth of about 20 cm. The pipe diameter of the pipe network is DN800-1200 (3 types DN800,DN1200, DN1000), and the pipe is concrete pipe. The length is 48 meters, the depth is 9 meters, and the construction period is about 20 years.

Step2

Considering the safety of the light frame in the sinking position, the high-power light chain and headlight feet with good passability are adopted to ensure good curing and fast traveling speed.

Step3

In order to ensure the safety of the material when pressurized at the diameter reduction, first of all, the entire section of the lining material is reinforced with zipper tie cloth. Secondly, in order to prevent the inner membrane from being scratched and scratched when the lamp is running at the diameter reduction, the inner membrane of the material is specially thickened in the factory production. This is a key step to ensure that the inner membrane can be successfully removed in the later stage.

05 Construction site atlas

Previous:No More

Next:The first ultra-long distance large pipe diameter UV curing construction case sharing