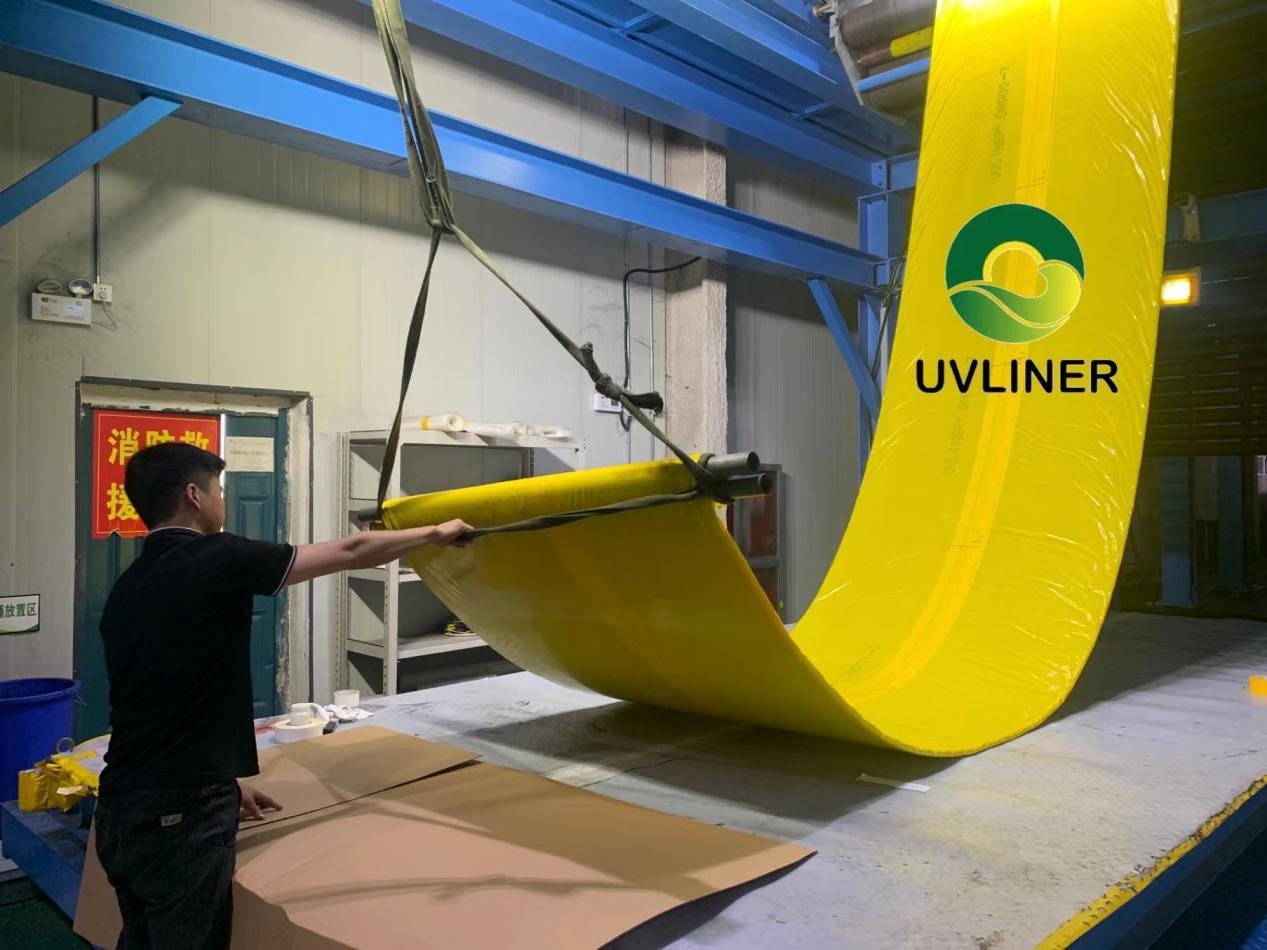

The first generation of prepreg CIPP UV-curable hose products, its registered trademark is UVLINER?, its technology comes from European experts, the main raw materials are from the actual engineering verified suppliers, the selection of special raw materials suitable for the water quality environment of the drainage pipeline, these raw materials have their own characteristics suitable for the UV-curable process requirements.

The selected special resin for the drainage pipeline repair process, European brand, belongs to the polymer material, the formation of a dense and stable grid structure after curing, which can resist sewage corrosion for a long time, good temperature difference resistance, high strength, good infiltration, good permeability, suitable for ultraviolet light through

The glass fiber selected is an internationally recognized alkali-free corrosion resistant ECR class glass fiber, which enhances the ring stiffness and stability of the inner lining. Special stitch design ensures resin content and impermeability of lining

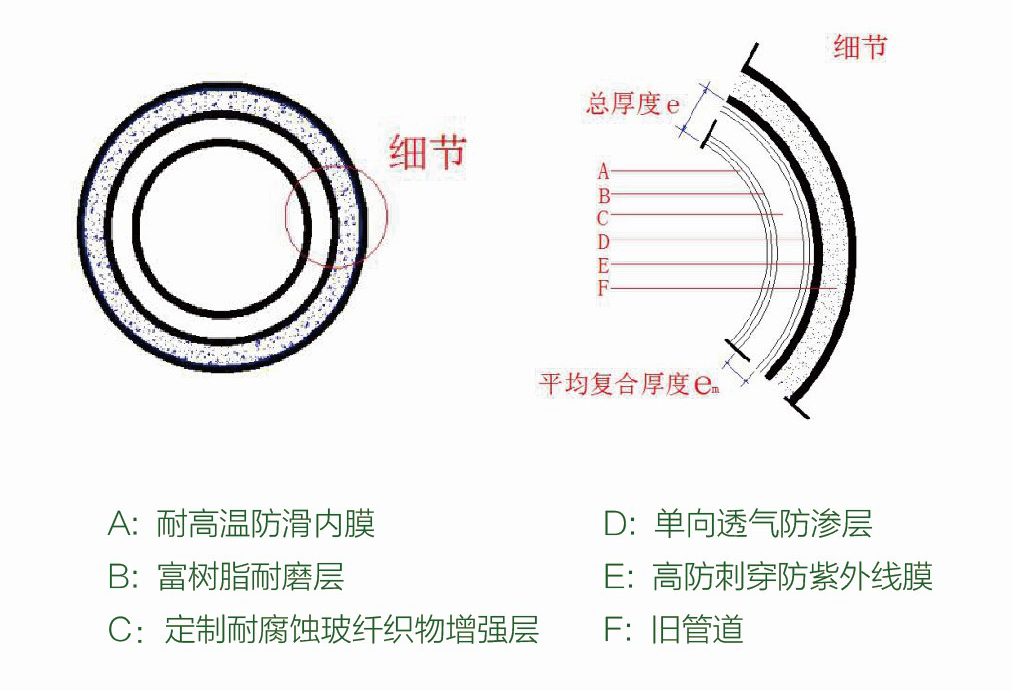

The selected inner layer has high temperature resistance on the outer layer, mainly referring to the local high temperature generated by resin curing; High puncture resistance, with a certain roughness on the inner layer to prevent the lamp foot from slipping, and nearly 100% UV light transmittance

The selected outer film has anti UV function, puncture resistance, corrosion resistance, and aging resistance, and is a key material to ensure the storage life of the hose.

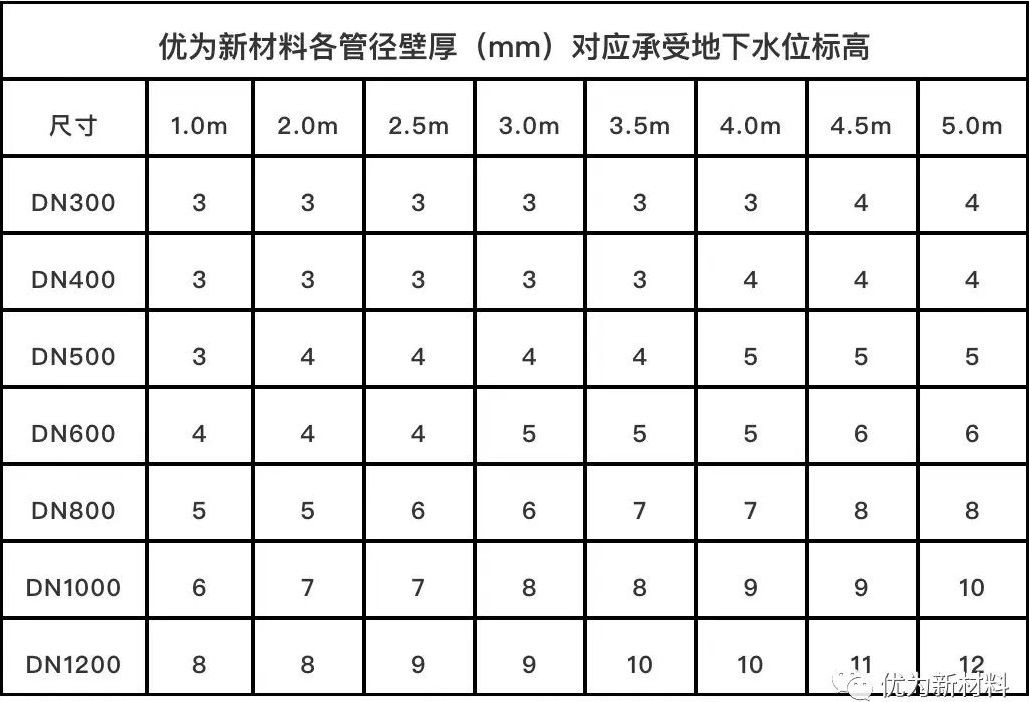

The flexible hose has a certain amount of expansion performance and ADAPTS to changing working conditions by using the glass fiber sutured lapping technology. For example, the hose of DN300 can repair the original pipe of DN290 to DN310. There is enough margin in the thickness to ensure that the design thickness is met.

Verified in the third-party professional laboratory, the overall vacuum filling process is reasonably optimized according to the material characteristics, reducing the defects such as bubbles and dry spots in the lining, and forming a tight lining layer after curing

Add special wear-resistant layer, improve the lining to prevent sewage corrosion and wear

Add multi-channel digital quality control process, special technical quality department, quality assurance data retention for three years

The hose can be used without refrigeration for up to three months after delivery; Constant temperature storage conditions, the warranty period can be up to six months;

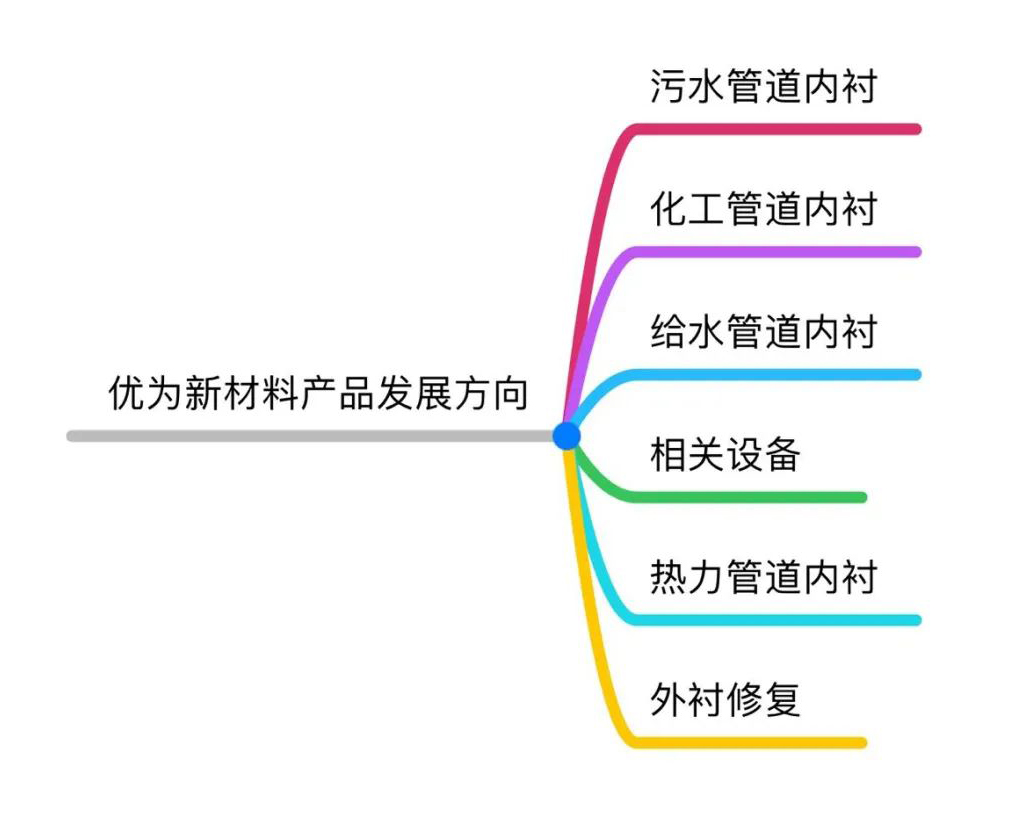

UVLINER ? The hose specifications range from DN180-DN2000, 3mm to 18mm, and can be produced in one go with a length of up to 310 meters. Zhejiang Youwei New Materials Co., Ltd. is developing the second generation pre impregnated CIPP UV curable hose product, with a bending modulus of up to 18000MPa, which is about to be mass-produced.

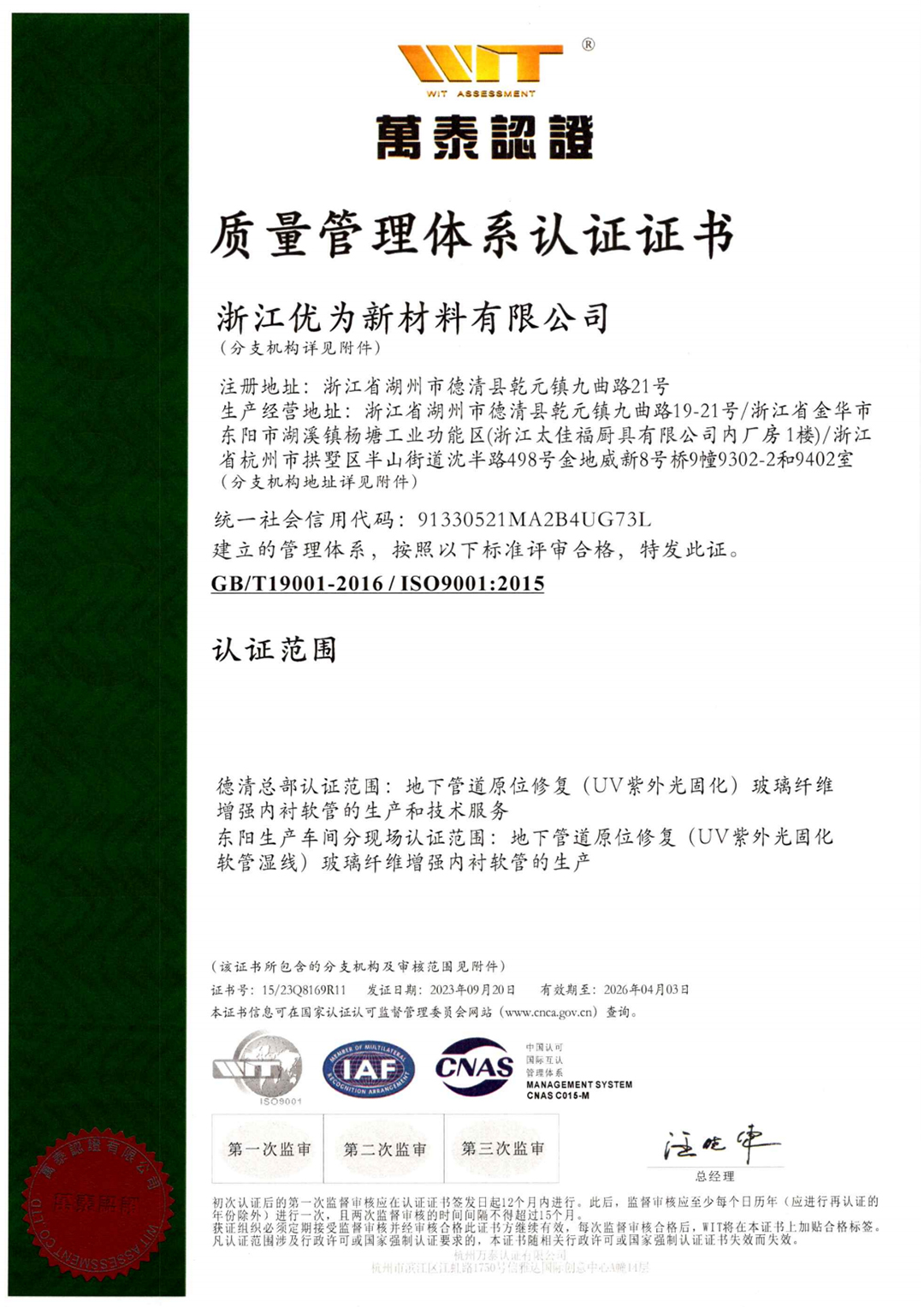

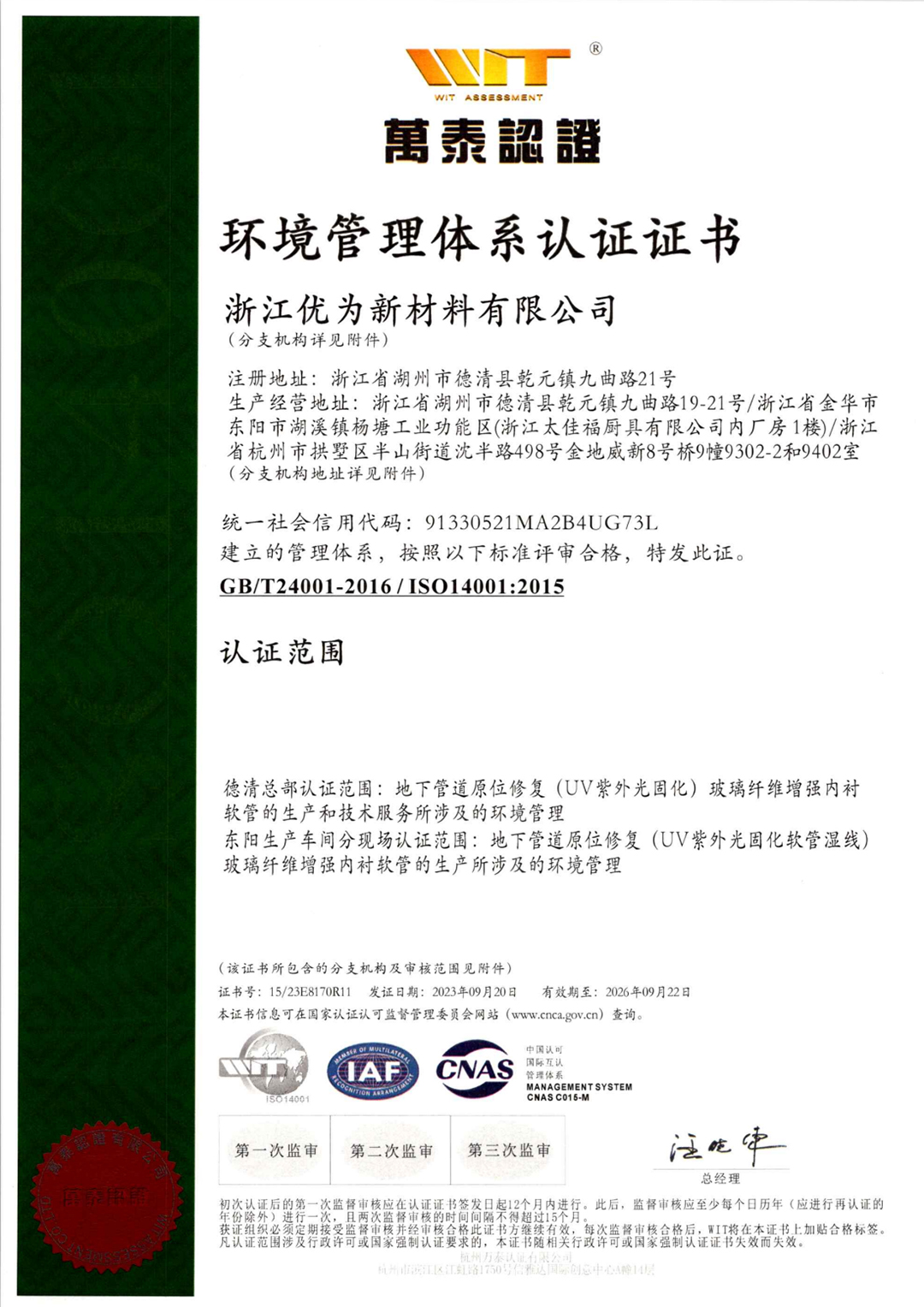

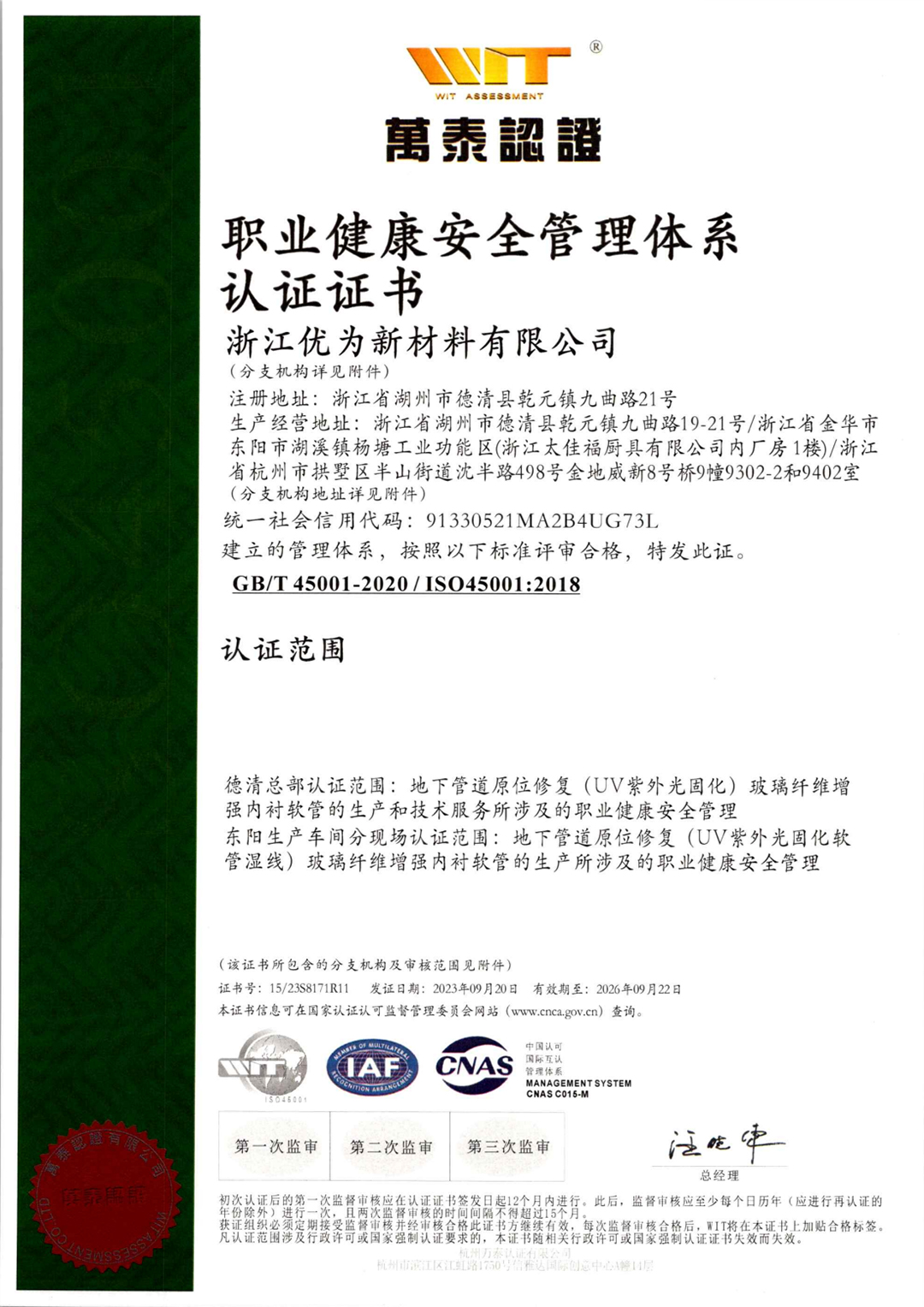

Zhejiang Youwei New Materials Co., Ltd. adheres to the TQM total quality management concept, takes product quality as the core, and establishes a set of scientific, rigorous and efficient quality system to provide all activities to meet the needs of users.

1. All raw materials can be put into production only after they have passed strict warehousing inspection

2, raw materials after quality control inspection, into the qualified warehouse. In the production stage of the dry pipe, the quality department should strictly control the size of the dry pipe, and each layer should be checked repeatedly by more than 2 people. The size error is controlled within +2mm, no negative error, to avoid the generation of later folds. In the hose production stage, the quality department evaluates the infiltration rate and wettability of the resin paste, and inspects it one by one with a special light source to ensure that all the glass fiber is infiltrated. Arrange three infiltrating inspection procedures in the whole process to avoid the defects of one inspection.