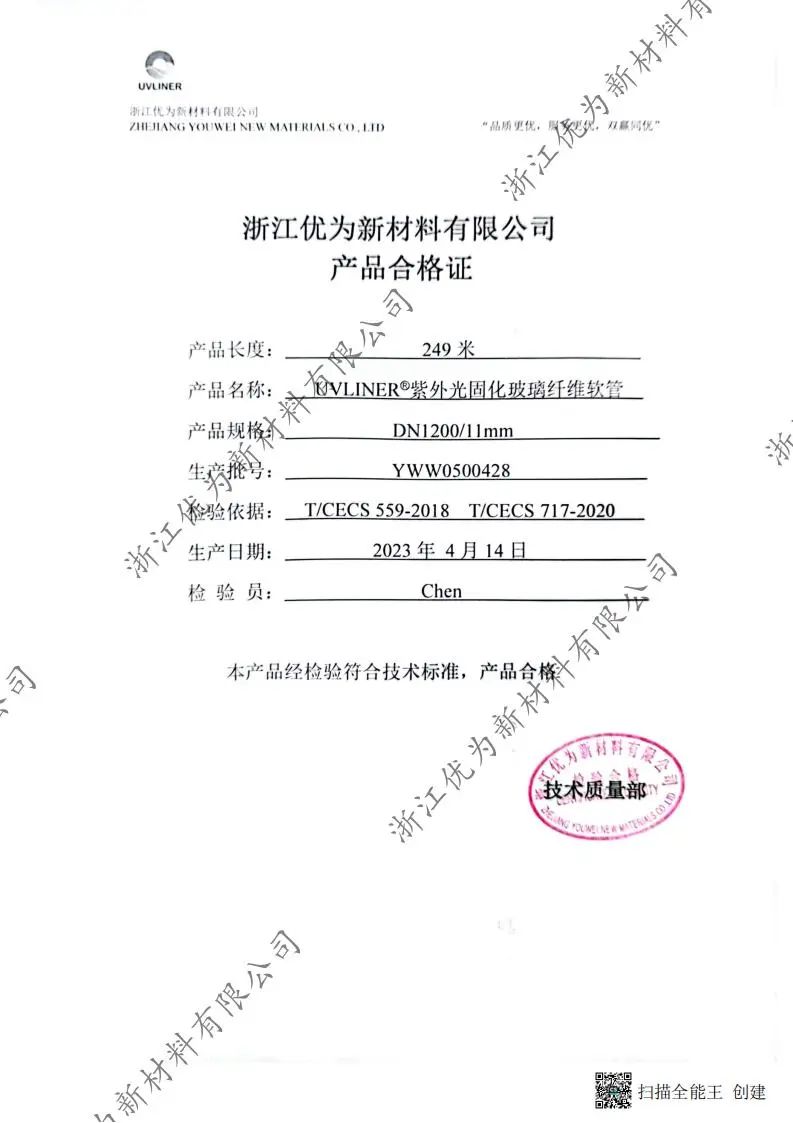

On May 16, 2023, the "Chengyang News" of Chengyang District, Qingdao City, covered a record-breaking construction project in China. The project was constructed by Qingdao Yijiaxing Municipal Garden Engineering Co., LTD., and the material was UVLINER? hose from Zhejiang Youwei New Materials Co., LTD. This project is the first large-diameter ultra-long-distance UV curing construction in China. The cooperation of materials, equipment and construction parties has made it a complete success at once,which is gratifying! Since its establishment, Youwei New Materials has been striving to accept challenges and constantly break through itself. After the construction and repair case of ultra-thick DN1850-18mm pipe diameter in May 2022, the success of this project will become a classic milestone in our material supply case!

Delivery site drawing

Case background

Project Overview:This project is located in Qingdao, Shandong Province, and the construction site is next to the underpass railway bridge, which is a main sewage pipeline from east to west in this area. Therefore, it is difficult to repair the pipeline by using excavation methods. The original length of the pipeline is 246.5 meters, with no intermediate wells, making it impossible to repair in sections. The total length of the material customization is 249 meters.

Scheme selection:The owner, designer and construction party considered various factors, and ultimately adopted the trenchless CIPP UV curing process to repair it.

Everyone may also be interesting in knowing what problems will be encountered during the production and construction of materials with large-diameters and long -distances, and what countermeasures are needed? Let's start from the source of material production to answer!

Q1: What are the difficulties in the production of UV-curable hoses with such long distance and large diameter?

A:The material length of 249m means that the production time span is extended, and the patience of workers is especially tested under the premise of ensuring the quality of materials. At the time, the production time of this hose was as long as 13 hours. And our workers were on pateol for 13 hours without interruption to ensure that the material was uniform in thickness during the production process. It was a test of workers' willpower!

Material bottom plot

Q2: How much does this particular UV-curable hose weigh? For such a weight, how to ensure the safety of the material transportation process?

A:The weight of the material is close to 20 tons. Therefore, we needed to ensure its safety on the packaging to avoid damage during transportation. Therefore, we added 40 galvanized pipes inside the package to distribute the weight of hose materials in the box, and installed two channel steel at the base to strengthen the packing box. In addition, there are a clear description of the materials on the package.

Q3: How to ensure the stability of DN1200-11mm-249m UV-curable hose?

A:The stability of the material is not related to the length, but to the characteristics of raw materials.

Therefore, before the production of DN1200-11mm-249m, we have used the imported raw materials to produce in the corresponding proportion according to the length and thickness of the material. Combined with our real-time monitoring of the production of hoses, to ensure the quality of materials. Especially in the construction of this project, the stability of the material is particularly important.

Production site drawing

Q4: What are the difficulties in the construction of this project?

A:Domestic pipe network repair has not been carried out such a long distance large diameter of the ultraviolet curing construction. During the early stage of the project, the construction and equipment parties conducted multiple technical clarifications with our company to ensure the smooth completion of the construction. There are two difficult factors:

1. Psychological pressure test for construction personnel

Due to the high cost of the whole project, if the operation is wrong in a certain link of the restoration, it will cause the whole project to fail and result in significant losses.

2. Communication, coordination and cooperation among the three parties

This restoration project involves the cooperation and coordination of construction, equipment and materials, which requires communication in the early training and consistent discussion on the technical plan, and cooperation in the construction process is crucial.

Live interview chart