On June 30, Youwei New Materials Co., Ltd. celebrated its fifth anniversary. At the same time, The production of the 12000 segment of UVLINER ? UV cured hoses has been discontinued. Up to this section, we have produced and sold close to 700 km of UV-curable hose to nearly 300 pipeline restoration projects. Our A supply or collection service projects are more than 15 . The accumulation of a large number of cases from DN200 to DN1850 has laid the foundation for the leap of UVLINER? from an annual output of 50 km to 450 km. Solid raw material quality control, continuous production experience and technical service capabilities are all inseparable from the experience accumulated in the production of these 700 km products.

Today, Xiaoyou has witnessed the rapid development of the domestic drainage pipeline repair industry and is proud to be a member of the industry. Then Xiaoyou plans to share some classic application cases, UVLINER ? raw material quality control, experience in continuous production, and technical service capabilities. Uncover the mystery, take you to find out.

Share the series with you

01 Classic Case Series

It mainly shares the application of UVLINER? UV-curable hose in some representative cases with relatively difficult construction, complex working conditions of the original pipeline, and analyzes from many aspects such as material production, transportation, and construction.

02 "Raw material Quality Control Series"

In the era of the CIPP technology rapid development, innovation, iteration, UV curable hose material are an important component. It is inevitable that there will be uneven quality control in the factory. Therefor, the construction party, equipment manufacturers, material manufacturers need to fully understand and meet the technical requirements of the process , in order to get a good repair lining delivered to the owner. Therefore, Xiaoyou hopes that by taking this series of technical public number, you can learn more about the details of the selection, quality control and management of some key raw materials of UVLINER? UV-curable hose, and explore the quality control.

03 "Production and technical service capacity sharing"

Uv curable hose is a factory-produced prepreg material that is cured by the construction unit at the construction site to form a pipe liner. Therefore, the quality control of the production process is very critical. Because at the site, the eye can not see the inside of the material before pulling in, and problems are found during construction, such as glue flow, uneven thickness, wrinkles, dimensional deviations, etc., which are difficult to deal with, and will inevitably bring defects in the lining after curing.

The excellent technology lecture hall has opened!

Speaker Introduction -- Li Hongyang

Li Hongyang, currently working as the general manager of Zhejiang Youwei New Materials Co., LTD., graduated from Beihang Material Department with bachelor's degree and Tongji MBA. She has been deeply engaged in the composite material industry more than 20 years, and has gained profound accumulation in the work of technology research and development, regional sales, and new market development. In 2009, she joined Reichhold Company in the United States to understand CIPP resin materials and processes. In 2012, she entered the domestic CIPP repair industry and participated in the introduction of the first European UV-curable resin. Witnessed the rapid development of CIPP UV curing process, and committed to industry standardization with many years of technical experience, participated in the compilation of the following standards.

2016

Participated in T/CECS 559-2018 Technical Specification for In-situ Curing of Water Supply and Drainage Pipes

2021

Participated in T/CUWA 60052-2021 "Lining Hose for in-situ curing Repair of Urban Drainage Pipes"

2023

Participated in the compilation of the national standard of "Plastic pipe system for trenchless repair of underground non-pressure drainage pipe network Part 4 in-situ curing Method"

Process raw material introduction - resin

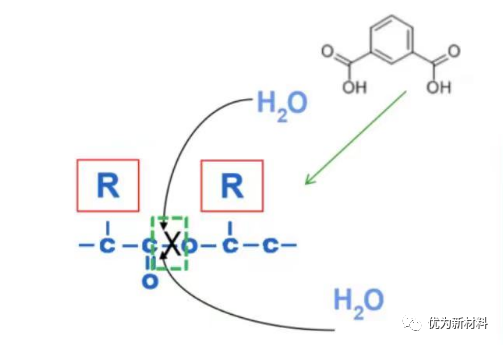

The resin used in the in-situ repair of the drainage pipeline UV curing process is generally an unsaturated polyester resin, which molecular structure contains non-aromatic unsaturated bonds, and the unsaturated monomer cross-linked reaction to form a large network of molecules with a complex structure, that is, the chemical reaction process from liquid to solid.

The cured structure is a thermosetting plastic, which becomes an insoluble, non-melting stable solid structure after curing. After reinforced with glass fiber and other reinforcing materials, it becomes a polymer composite material, which strength is higher than that of steel, duralumin and fir. It is a new material of light weight and high strength.

Process technology requirements for resins

The lining of the drainage pipe is in contact with the sewage for a long time during operation, and is worn by certain impurities flowing through it. Therefore, the lining resin requirements not only need to have strong mechanical strength, but also need to have good corrosion resistance to sewage, as well as suitable for UV curing process physical properties.

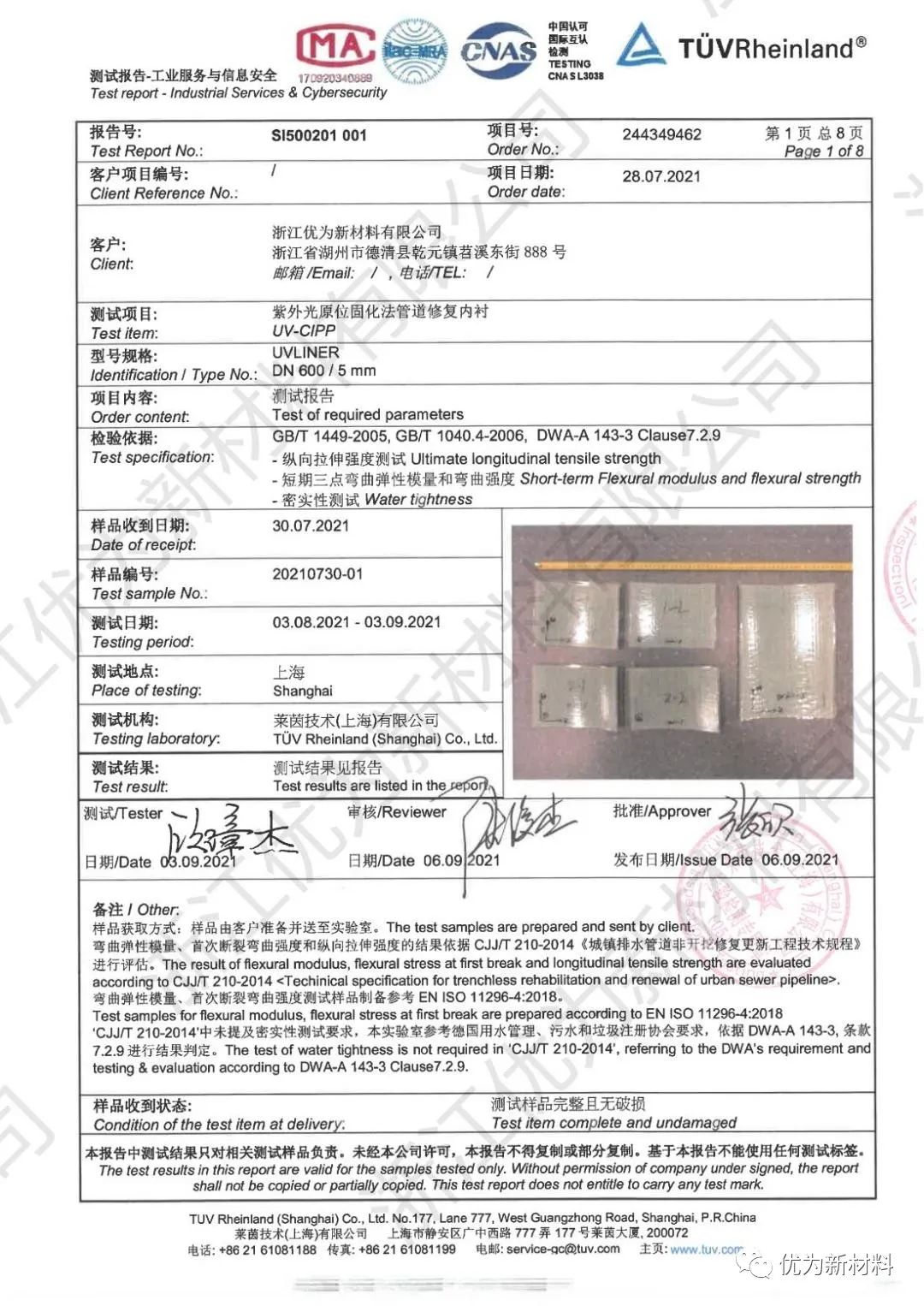

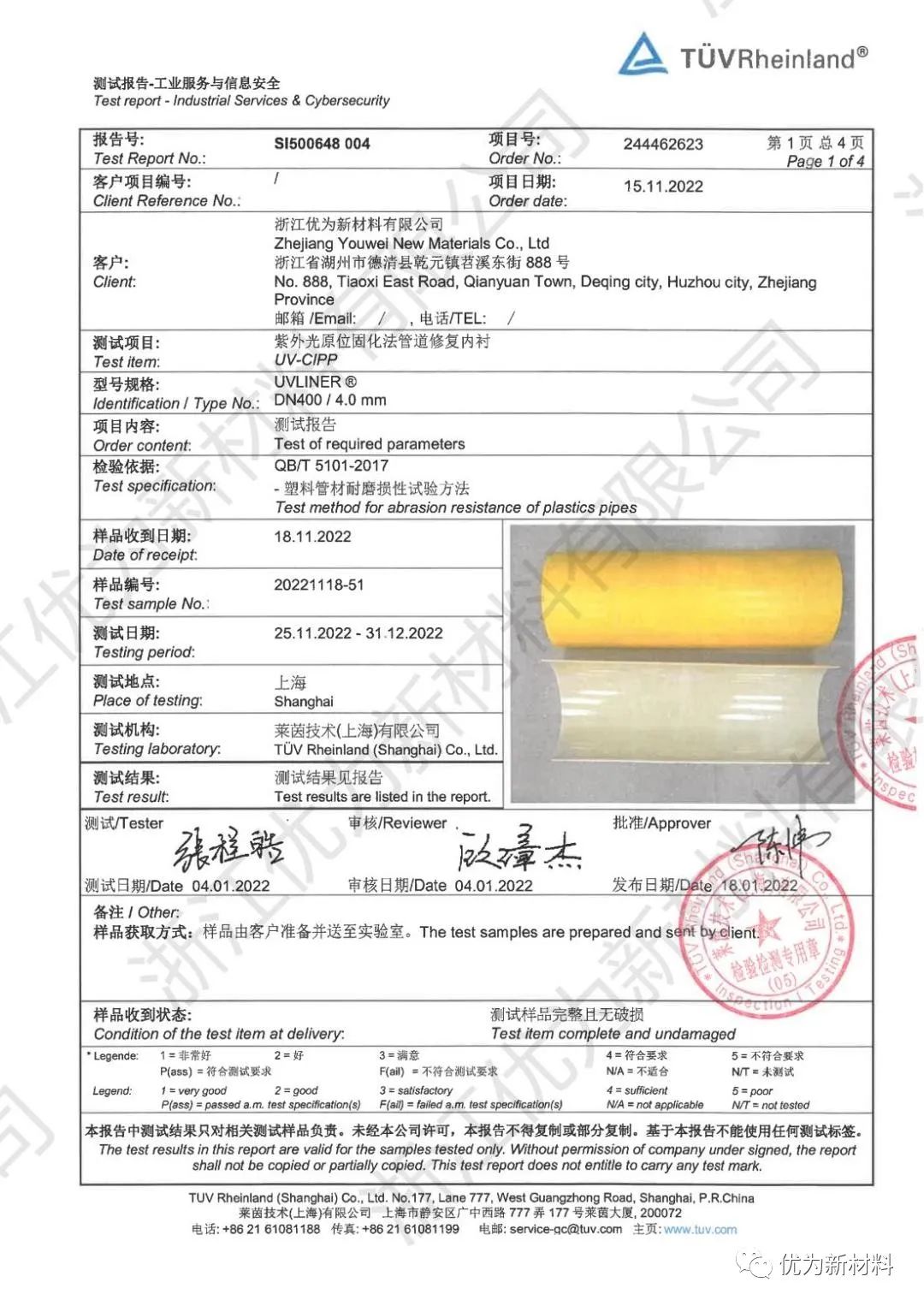

UVLINER ? Select the ISO-NPG unsaturated polyester resin supplier with a good reputation in the industry, which has high mechanical properties, excellent resistance to sewage corrosion, good transparency, and good structural stability after curing. And it has been verified through 10000 hour load creep by the German IKT organization, long-term corrosion resistance by the TUV organization, and millions of wear-resistant tests.

For resin quality control

Before the production of UVLINER?, the Technical Quality Department will carry out a strict warehouse inspection, which mainly covers:

1, Light transmission test

2, Sewage corrosion resistance chemical performance test

3, Batch stability test, long-term comparison of multiple batches

4. Test whether the resin can be rapidly cured by ultraviolet light in the wavelength range of 365-420 nm

5, Moderate heat release, not violent heat release, to meet the curing of thick lining

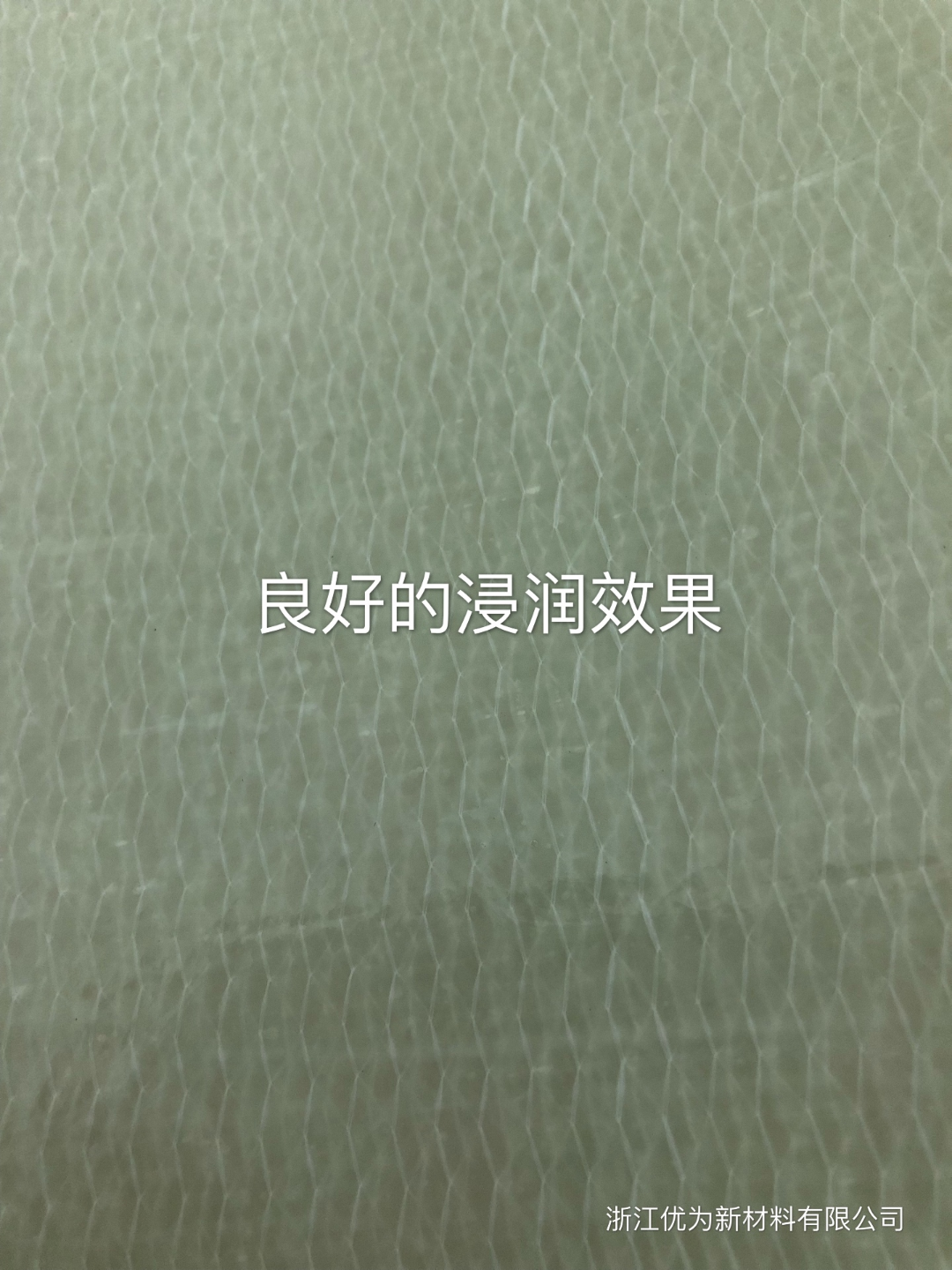

6. Match test with glass fiber

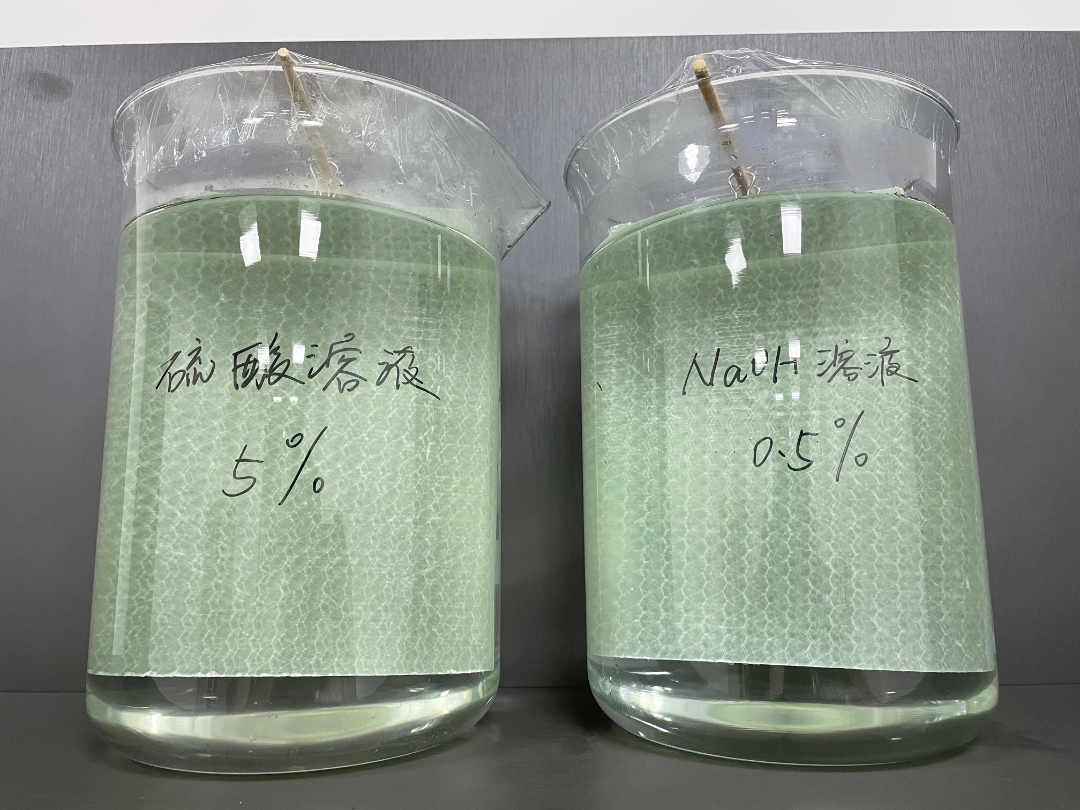

Corrosion Resistance Test (1)

Qualified samples were soaked at room temperature, and the strength data met the requirements of T/CECS 717-2020

After the comparison sample was soaked at room temperature, the resin turned white and swelled, and the strength data did not meet the requirements

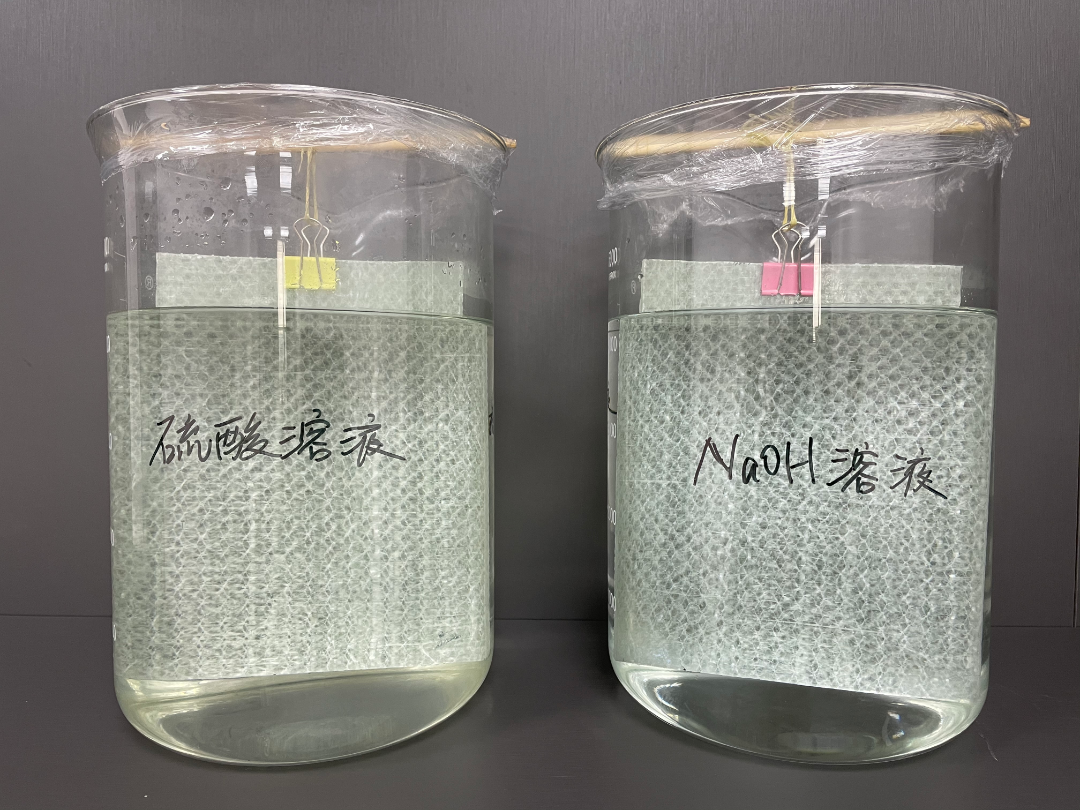

Corrosion Resistance Test (2)

Qualified samples were soaked at 60℃, and the test data met the requirements of T/CECS 717-2020

After the samples were soaked at 60℃, the samples were white and swollen, with subtle cracks, and the test data were inconsistent

Conclusion:

UV CIPP lining curing well can meet the service life of 50 years. But if the material is poor, the use of the lining will be corroded by sewage, as well as resin fall off and other defects, the service life will be seriously affected.

Therefore, the selection of resin with excellent performance for UV-curable hoses is one of the key factors.

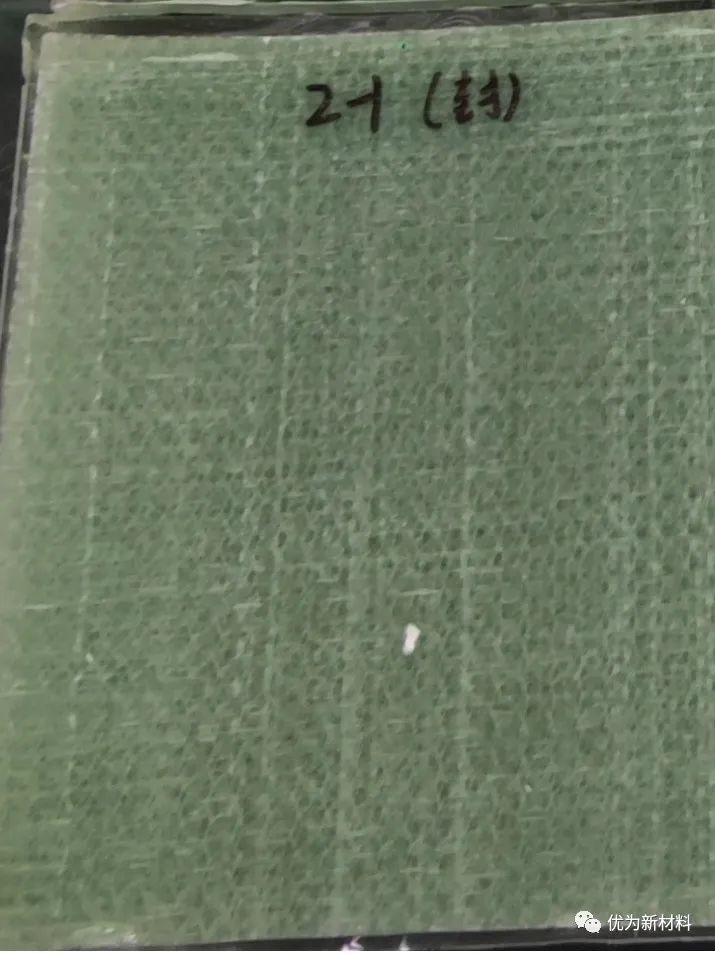

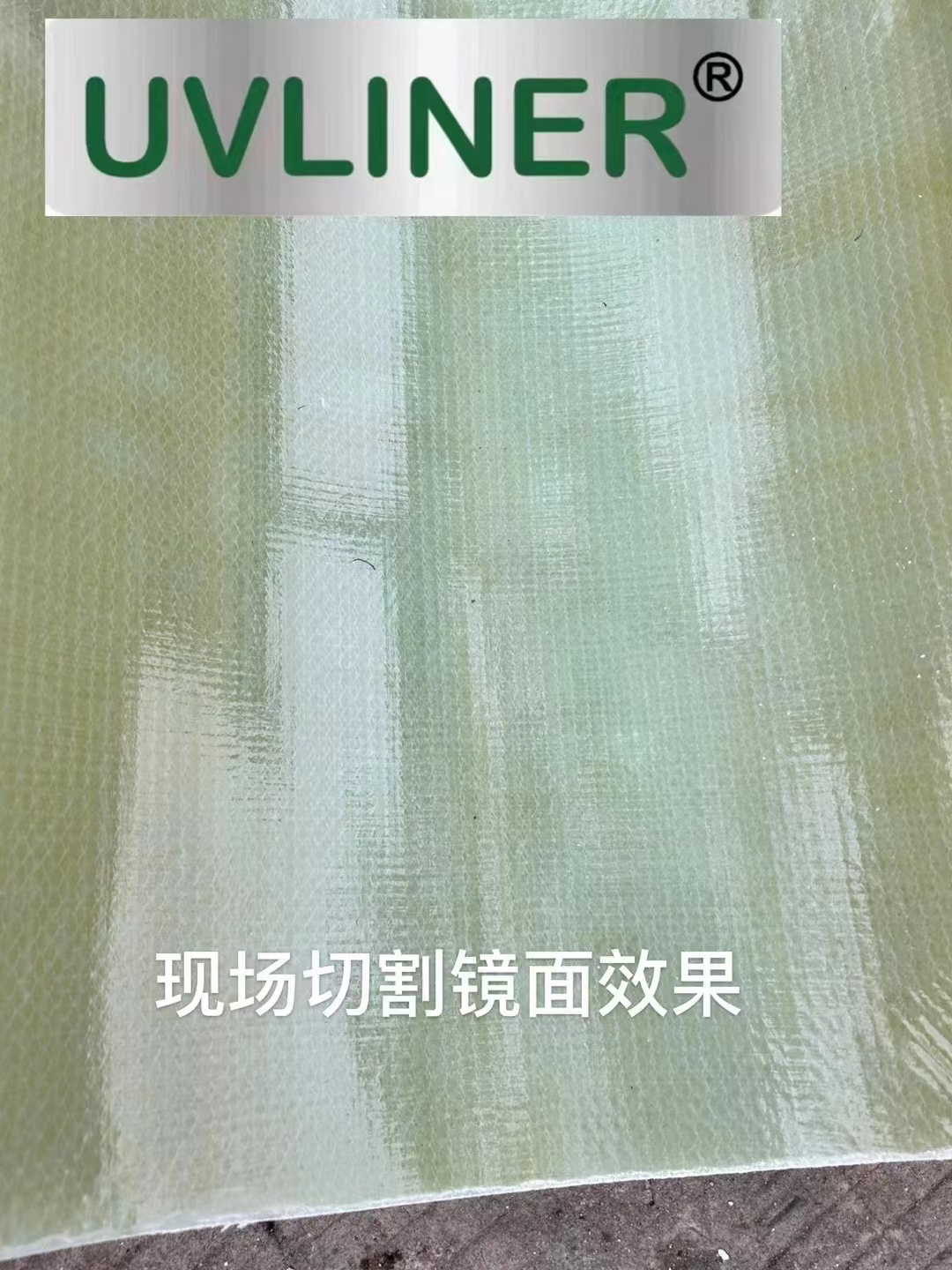

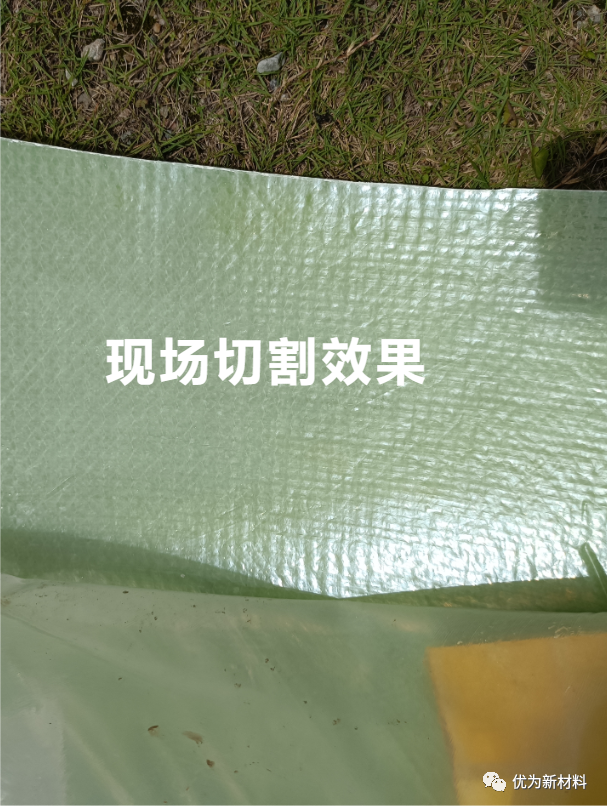

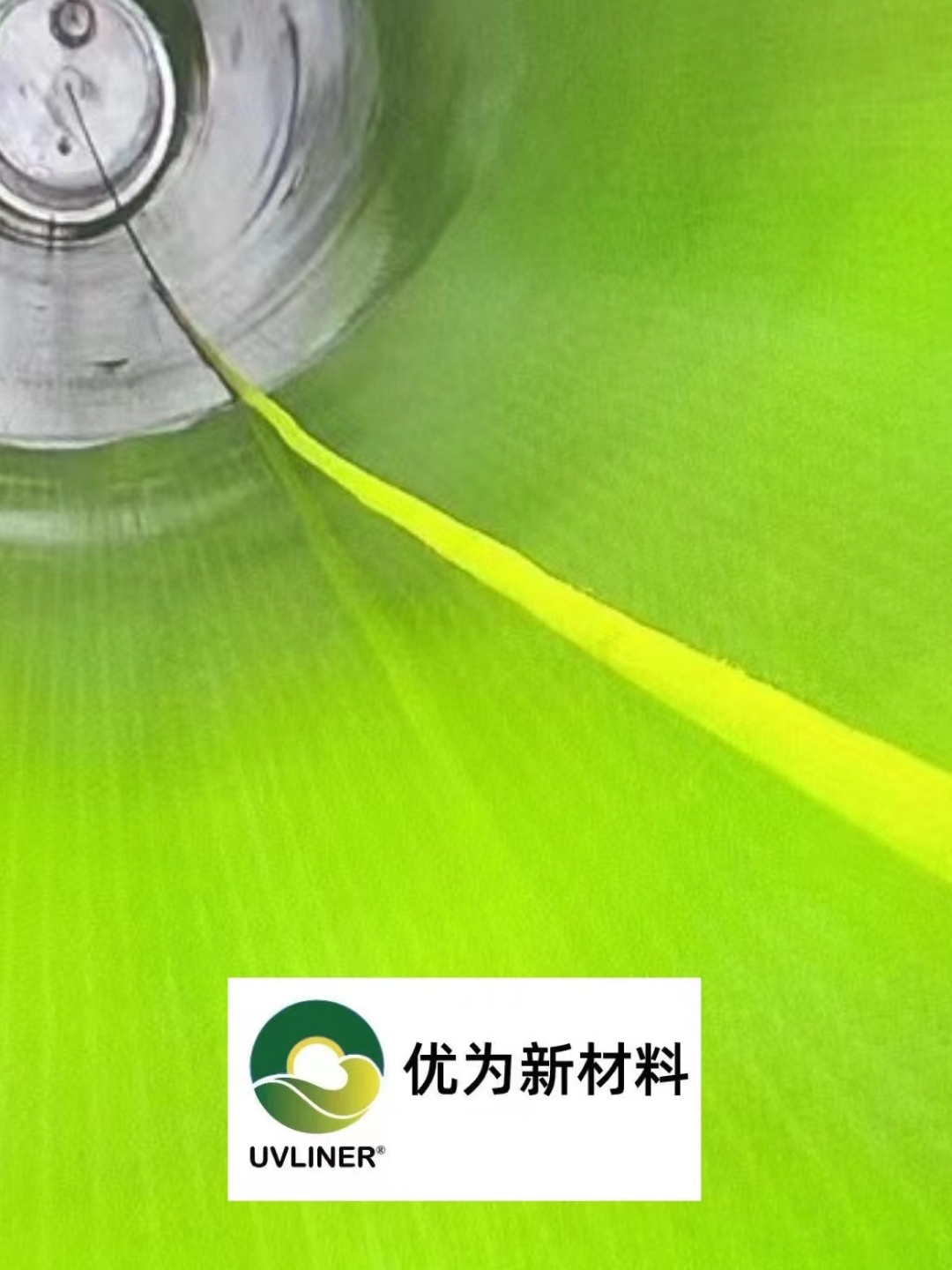

Atlas of qualified samples

Excellent for the lecture hall summary!

Resin is the key raw material of UV-curable lining, warehousing inspection not only focuses on strength, but also on process performance and corrosion resistance detection.

UVLINER UV-curable hose not only selects raw materials, but also manages the full quality of raw materials from warehouse inspection to production, packaging and delivery, which is an essential part of obtaining high-quality CIPP lining.

The production experience of 12000 pieces of material and 700000 meters of material has been cast into Solid technical foundation for UVLINER ? UV cured hoses.