UVLINER independently developed by Zhejiang Youwei New Materials Co., Ltd ? Since its official launch in the domestic market in 2019, UV cured hoses have been the preferred choice for many new and old customers as well as central enterprise project buyers due to their advantages of stable quality, complete specifications, professional service, and fast delivery.

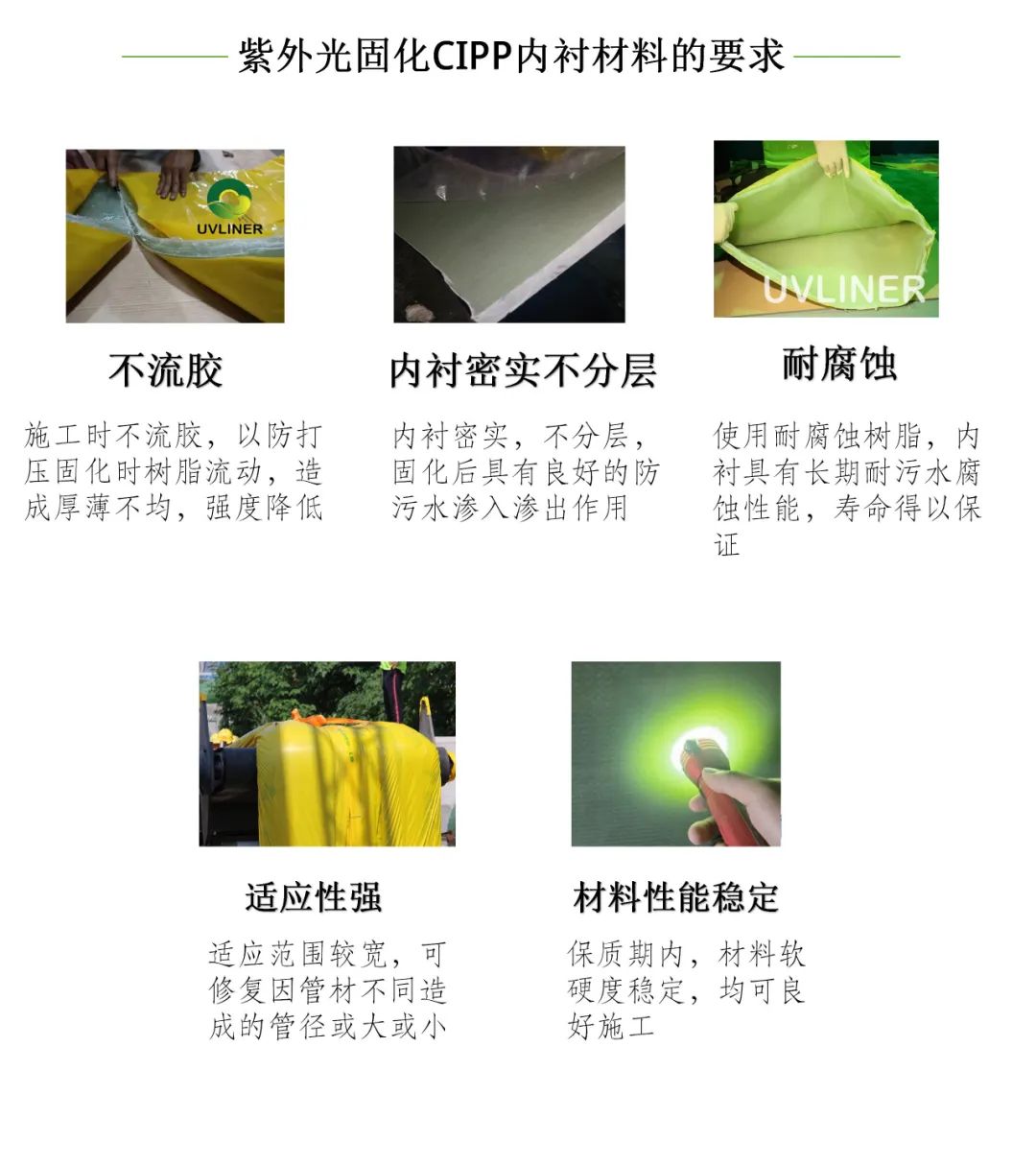

The construction difficulty and high cost of UV curing technology with large diameter pipes make the success rate highly valued by owners and construction units. In the face of project demands from all over the country, UV cured hose materials need to meet strict requirements such as being able to work anytime and anywhere within 24 hours to 3 months of leaving the factory, having a moderate soft and hard texture, no glue flowing during binding, low odor, uniform thickness after curing, good curing, and easy removal of the inner membrane. The Youwei New Materials Technology Team has mastered the requirements and equipment characteristics of many domestic construction teams, and timely adjusted the raw material ratio of production according to customer needs, ensuring the best state of products, improving customer satisfaction, and achieving the best construction effect.

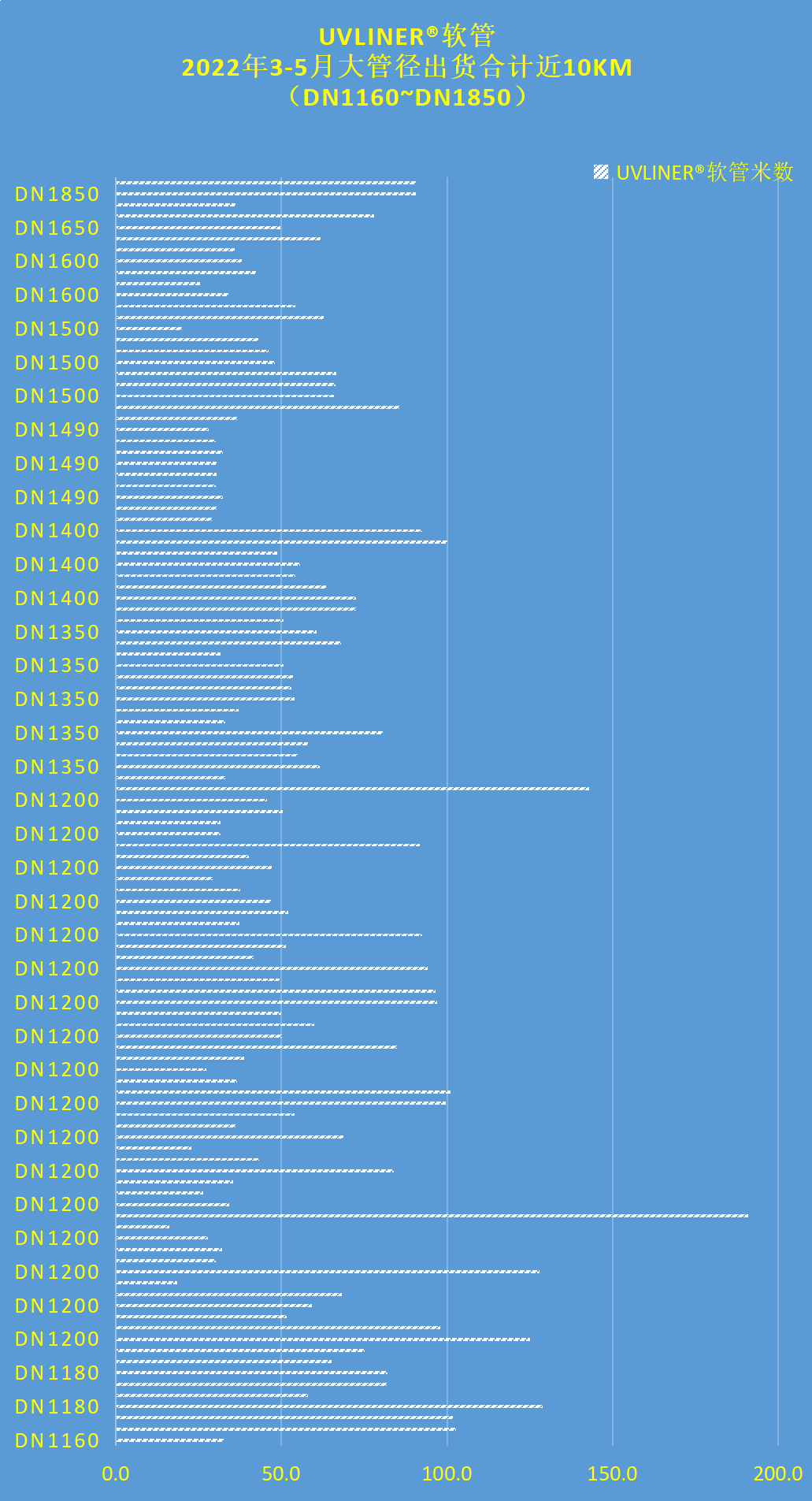

Supply of large diameter pipes

During the period of March May 2022, our company has supplied a total of 35 customers with materials with a diameter of DN1200 and above, totaling nearly 10km. The longest section is DN1200-8mm-191m, and the heaviest section is DN1850-18mm-90.5m, weighing 21 tons. No matter how difficult the challenge is, we, Youwei Youth, have completed repeated production tasks with the concept of "intelligent manufacturing".

Large diameter materials need to be strictly controlled at every stage, including production, raw material ratio, packaging, logistics, etc. In terms of the proportion of raw materials, it is necessary to accurately grasp the optimal proportion to ensure that the materials are not too hard, otherwise it is difficult for workers to stack materials during construction, which can easily cause material wrinkles; During production, the maximum width of raw materials is 5-6 meters, and the accuracy should also be controlled within 1-2mm, which is a great test of the patience of workers; When going offline, the materials are heavy, and how to pack them reasonably and quickly is also a test for the team; During transportation, perfect coordination between cranes and forklifts is also required.

The production process of large-diameter materials is complex, and for material manufacturers, accumulated experience is very important. Such a process has been repeated multiple times by Youwei New Materials, and has gone through 133 times in 2022!

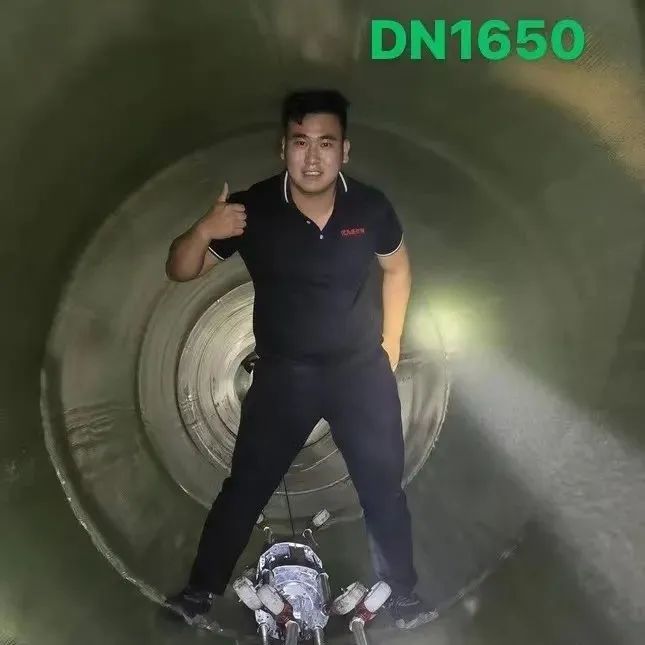

A collection of construction effects for some large pipe diameters

trength display

Zhejiang Youwei New Materials Co., Ltd. has a factory area of over 10000 square meters, with two dry hose production lines, two wet hose production lines, one packaging line, and key equipment for automated production lines imported from Europe. The finished hoses in the factory area are stored at a constant temperature, and regular products are stored for a long period of 5-8km. The daily production capacity can reach 2000-2200 meters.

Zhejiang Youwei New Materials Co., Ltd. has two wet pipe production lines, one with a production specification of DN180-DN1800; Another new production line was put into operation at the end of May, with a production specification of DN300-DN2000, which will be expanded to DN2200 in the future.

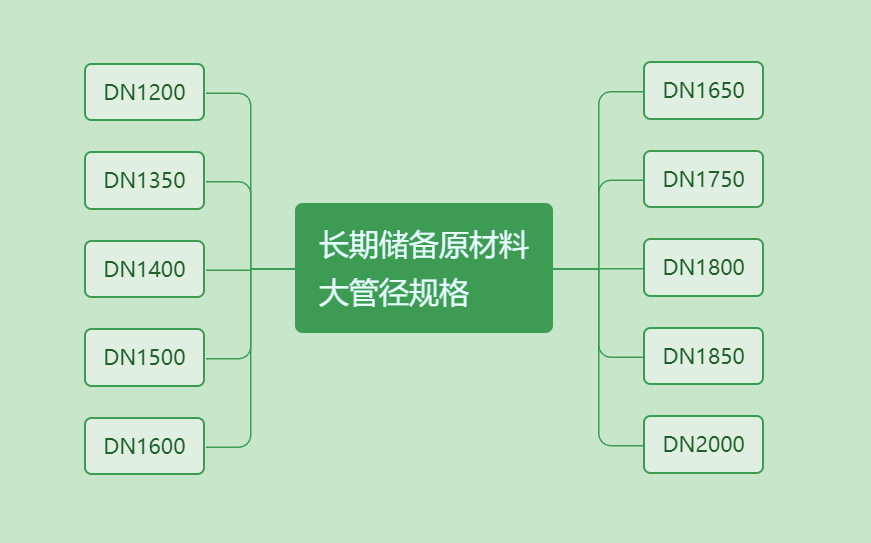

The large diameter specifications for long-term reserve raw materials are:

DN1200, DN1350, DN1400, DN1500, DN1600, DN1650, DN1750, DN1800, DN1850, DN2000, and materials of non-standard pipe diameters, please feel free to inquire.

The production of large-diameter materials requires high transparency inner film and UV resistant outer film imported from Europe, high-performance resin and fiberglass specially designed for CIPP, powerful equipment, excellent team, and your trust, trust, and trust!

Zhejiang Youwei New Materials Co., Ltd. was established in 2018. In the nearly five years of growth, whether it's samples of a few meters or orders of 191 meters of ultra long meters, we have always emphasized quality. Perhaps we should emphasize our team's professionalism, meticulousness, and dedication in our work, the meticulous calculation of every millimeter, and several technical discussion meetings held late at night, all of which reflect professionalism and quality in the details. I believe that the 133 trials of complex processes with super large diameters will enable us to cope more calmly in the future market!